RICHMOND, Va. (CNS) — While the coronavirus pandemic closed schools throughout the country, students at a Virginia Catholic school have turned to manufacturing personal protective equipment for health care workers.

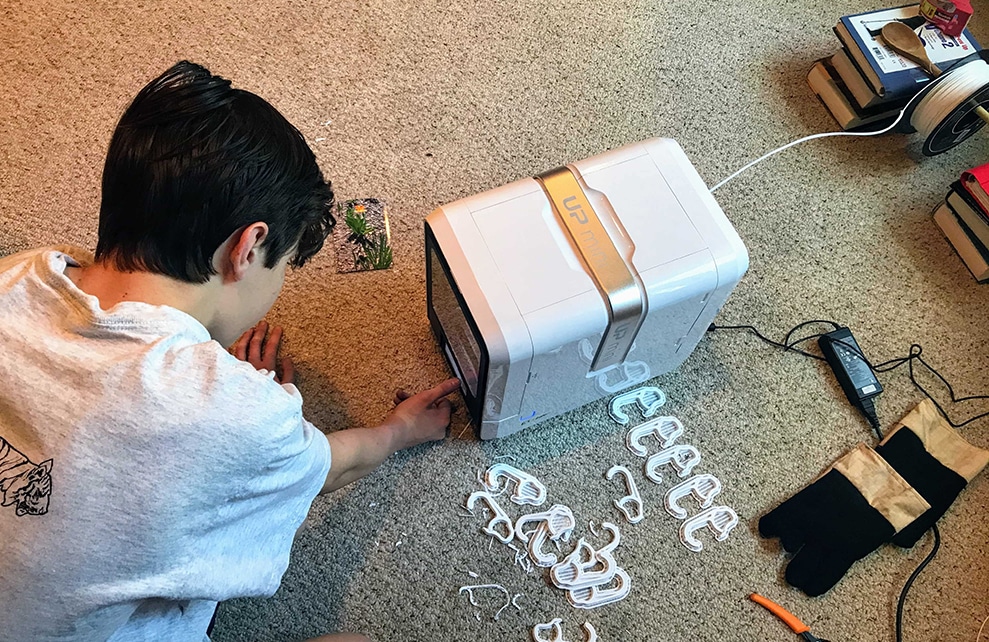

Using 3D printers, middle school students at St. Bridget School in Richmond, guided by their robotics teachers, produced much-needed equipment to make the job of the workers easier to navigate.

Eric De Boer, one of the school’s two robotics coaches, saw posts on social media about 3D printing helping in the response against COVID-19, the illness caused by the novel coronavirus.

“After the diocese announced we would not be physically returning to school for the rest of the year, I thought we could put our 3D printers to work during this pandemic,” he told The Catholic Virginian, newspaper of the Richmond Diocese. “Our school values service, and this seemed like a way for our students to serve our community.”

De Boer sent emails to his students and their parents looking for volunteers. Quickly, eighth grader Bridget Plank, 14, and seventh graders Hayden Veech and Anthony Pennock, both 13, replied. Turning their homes into makeshift factories, they have produced hundreds of items for health care workers.

The students said they were inspired to act by their faith.

“Jesus said, ‘Do unto others as you would have them do unto you,'” Bridget said. “So if I were a health care worker during this time, I would want people to help me and my co-workers in any way they could.”

Hayden added, “My faith taught me to treat others as you want to be treated. It would be wrong to do nothing.”

With their team assembled — virtually — they got to work. De Boer knew the school’s printers were too small to print large PPE gear like face shields and masks, but he was also sure that workers on the front line could still benefit from their help.

He connected with #MakeItThru Alliance, a group of engineers that has been coordinating efforts to produce and distribute 3D printed materials to local health care personnel and essential workers such as bus drivers and customer support staff.

Jean-Etienne LaVallee, an alliance leader, welcomed the students with socially distant open arms. He told De Boer there was a need for small items such as “door grabbers” and “ear savers,” which could be printed on smaller printers.

Door grabbers are small plastic devices that hook over door handles, allowing people to open doors without actually having to touch the handles themselves. The tool helps reduce spreading germs.

Ear savers are designed to reduce irritation brought on by wearing face masks. Each elastic ear band on a regular surgical mask hooks on to one end of the ear saver, alleviating the pressure on the ears themselves.

The ear saver strap, which can be adjusted for size, sits at the back of a person’s head. This provides relief to hospital workers who wear masks for several hours at a time.

While the robotics students have experience planning and producing objects, the effort marked the first time they have had the responsibility of manufacturing products on their own.

Each student has a printer at home. De Boer used video chat to give the students instructions for completing their projects. Once a print job is finished, each product is sanitized and placed into a plastic bag. They leave the bag in a “drop zone” at the school and members of #MakeItThru pick it up.

Hayden said health care workers appreciate the students’ work.

“They loved that we were helping out with simple tools that made working much easier,” he said.

After De Boer posted about the group on social media, several health care professionals expressed interest.

“In addition to the practical support this provided, there is also the emotional support felt when strangers reach out to help,” De Boer explained. “Knowing others around you care for you and are with you can provide a great sense of hope and encouragement.”

3D printing is relatively inexpensive. Each spool of filament — the printer’s version of ink — costs about $20, and each spool can make dozens of ear savers or door grabbers.

St. Bridget teachers are chipping in to help cover the costs. It takes one hour to print a set of two door grabbers and a half-hour to make an ear saver.

“It feels just as good to give to others as to receive things yourself,” Bridget said.